Leading-edge design innovation

The intelligent design of a driveline is very critical to ensure ongoing reliability. It is important that the power source, speed and universal joint angle are ascertained prior to specifying a shaft to suit any situation. We offer a full consultation and design service so your custom requirements can be met with products that deliver optimal performance.

Turret Driveline is our legacy. With over sixty years of experience, we are New Zealand’s most trusted supplier for all driveline needs. Turret drivelines and componentry are designed, and hand built to extremely high standards here in our state-of-the-art Beattys Group Auckland facility, and backed by our dedicated and accessible team.

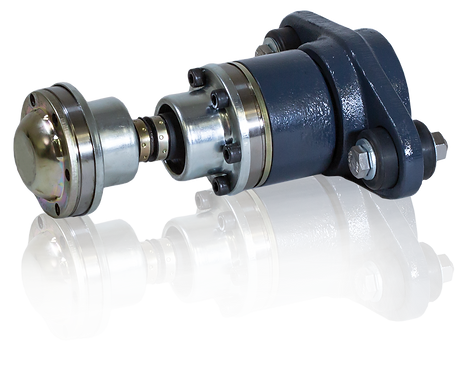

Benefits of a Turret thrust bearing.

In all marine applications with conventional shaft drives, the thrust and vibration from the propeller is transmitted axially through the shaft to the coupling, through the transmission, and then to the engine.

TRADITIONAL INSTALLATION:

The propeller shaft is mounted directly to the gearbox or engine, which requires time consuming and precise laser alignment. The thrust is transferred directly through to the engine, requiring stiff engine mounts which transmit vibrations through to the hull. Regular angle and height adjustments are also required to monitor operational wear.

TURRET THRUST BEARING INSTALLATION:

The propeller shaft is mounted directly to the thrust bearing assembly, and then a universal cardan shaft or CV shaft completes the connection through to the engine or gearbox. These installations allow for a wide range of alignment flexibility, including allowing the engine to be mounted horizontal in the vessel. The thrust is absorbed within the thrust bearing assembly shaft of the supporting bulkhead, and transferred directly to the structure of the vessel rather than the engine or transmission.

VS

BENEFITS:

-

Reduces noise – up to 50%

-

Prevents high frequency vibrations

-

Increases life of drivetrain componentry including cutlass bearings and engine mounts

-

Flexibility with engine installation and alignment

-

Eliminates regular operational angle adjustment

-

Custom flange adapters

-

Allows for softer engine mounts which further reduce vibrations and noise

-

Removes prop thrust off the gearbox, increasing service intervals and overall lifetime

-

Prevents high frequency vibrations from causing wear and damage to the prop shaft drivetrain

-

Saves time and reduces costs with less requirements on propeller shaft alignment

RANGE AND CAPACITY:

-

Models range from 3kN to 61kN Power rating up to 2000Hp

-

Internal taperloc designs to suit up to 4.0’’ propeller shaft diameters

-

Pleasure and commercial duty rated

Specifications:

THRUST BEARING SOLUTIONS TO SUIT EITHER CV SHAFT OR CARDAN SHAFT APPLICATIONS:

"As designers of high-end luxury motor yachts, we are always striving to develop and improve our product wherever possible. In my opinion putting the propeller shaft through a thrust bearing is the ultimate driveline installation. Taking the thrust directly into the structure rather than through engine mounts dramatically reduces vibration and noise. Beattys are our go-to for anything related to thrust bearings and universal joints that we use whenever the situation and installation allows. The team at Beattys is very knowledgeable and always deliver the correct solution for each individual project, on time and to the highest standard."

Bill Upfold

Elite Marine Design Ltd

Find out how we can create a driveline solution for your needs.

Your problem our passion.

Call us today.

TALK TO US

Our mission is you. We aim to deliver the best possible in driveline design, manufacture and componentry for whatever your need or circumstance.